Flexible TRANSFERS are machines that can be placed conceptually between machining centers and traditional transfers, gaining flexibility and keeping the production characteristics for big lots.

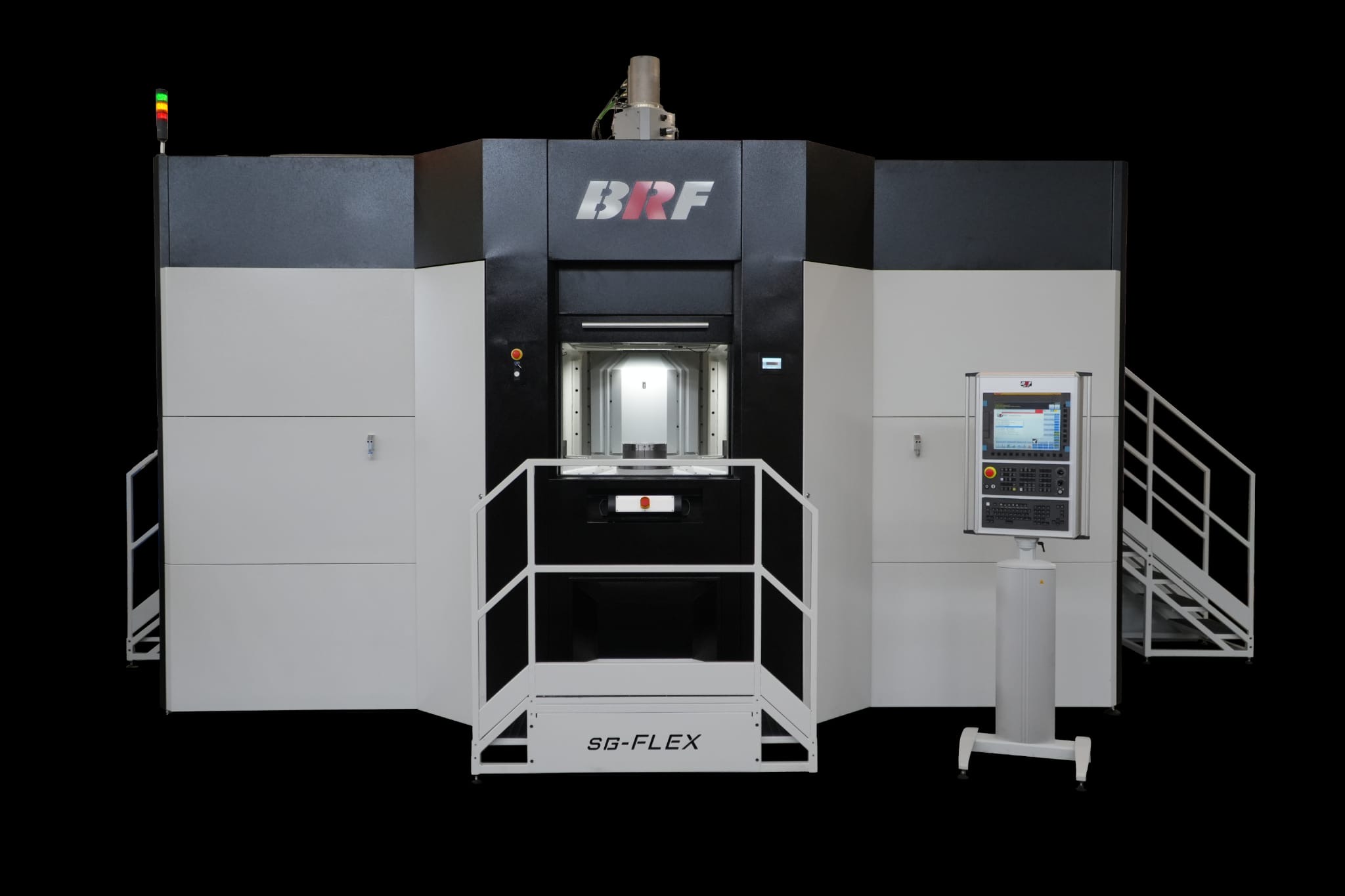

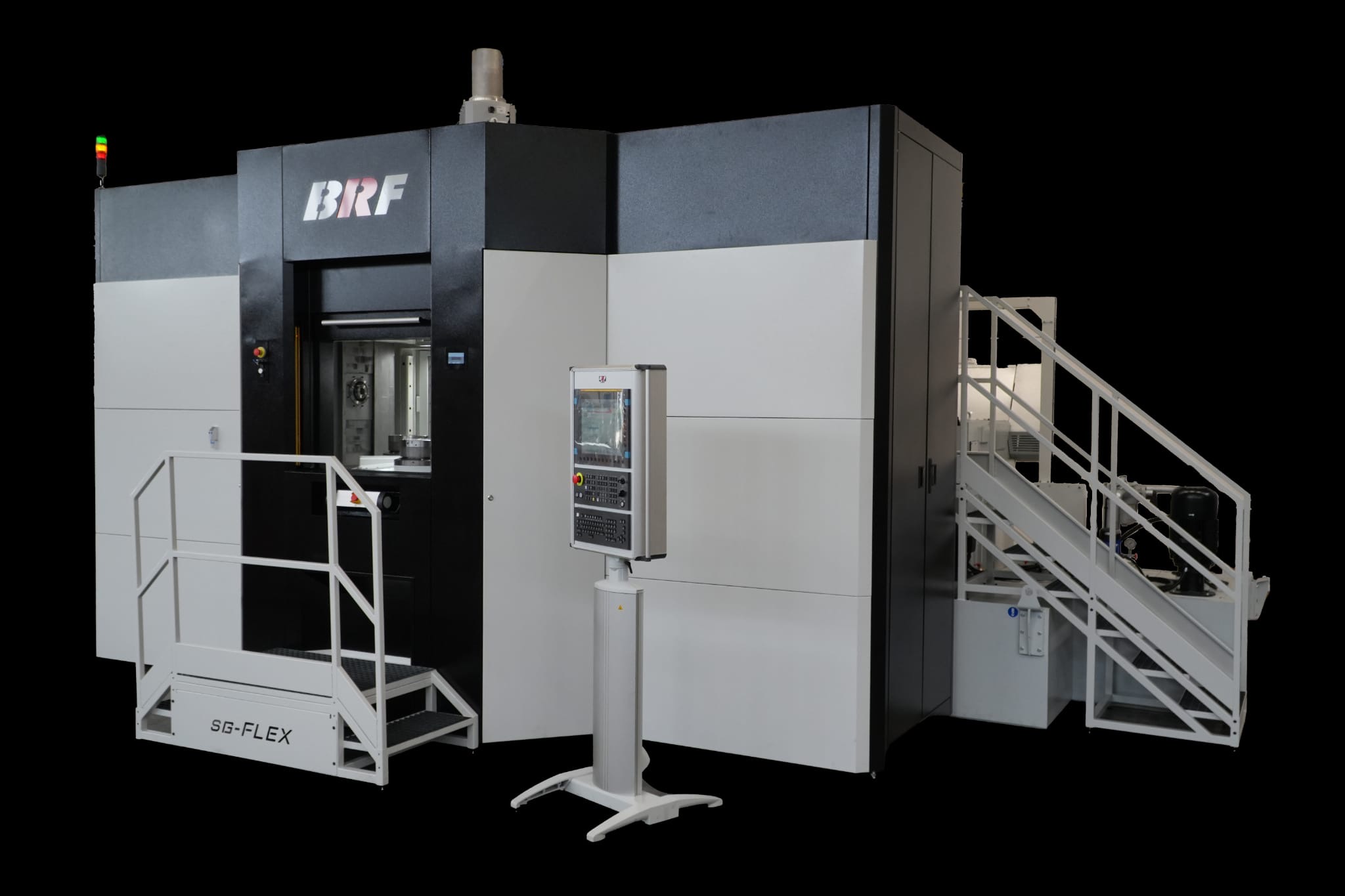

The multicenter SG FLEX is a configurable machine that is placed between traditional transfers and machining centers, which stands out for its remarkable flexibility and high productivity.

SG FLEX is composed of:

-

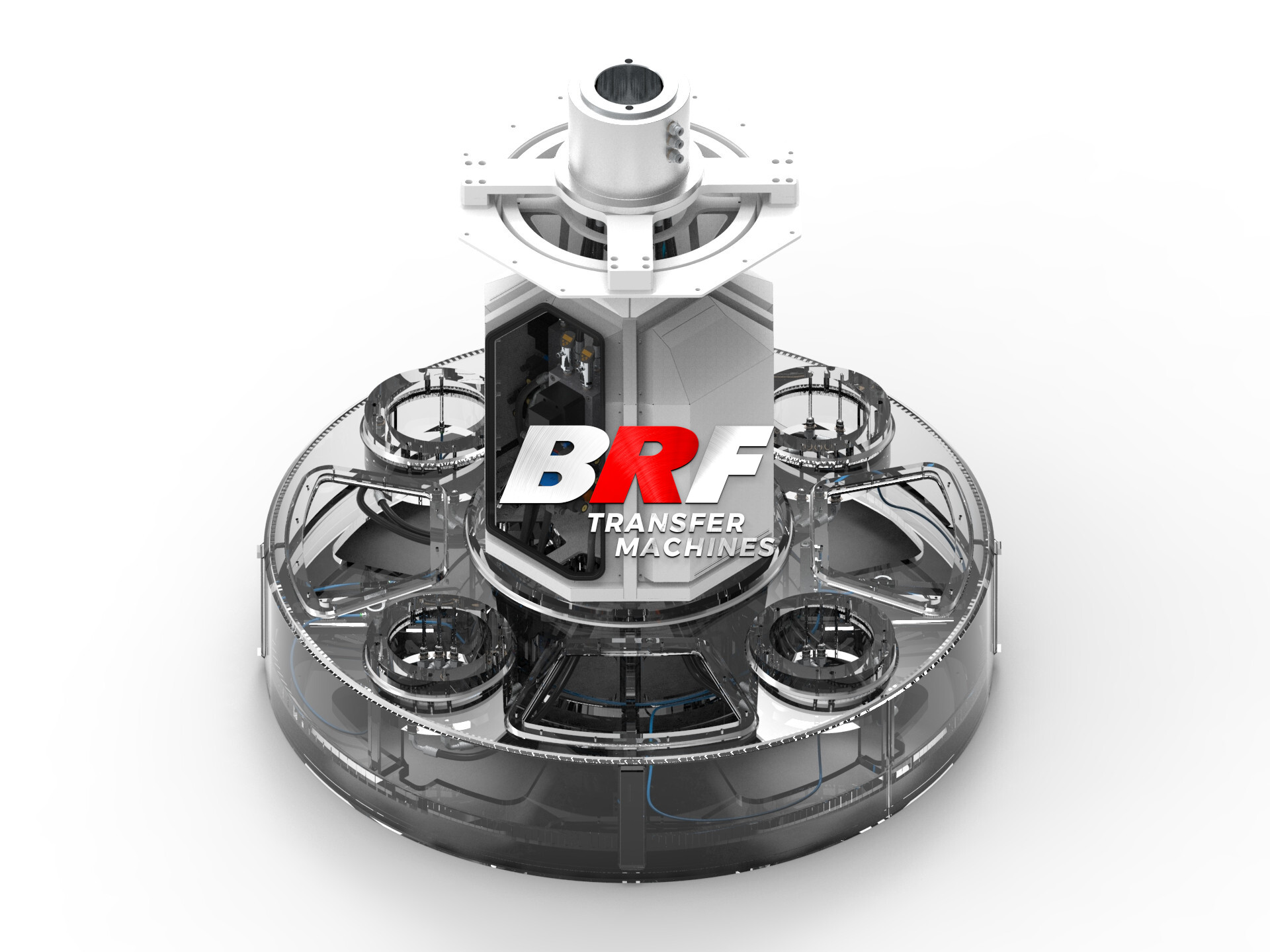

Possibility of different configurations: 4, 5 or 6 stations

-

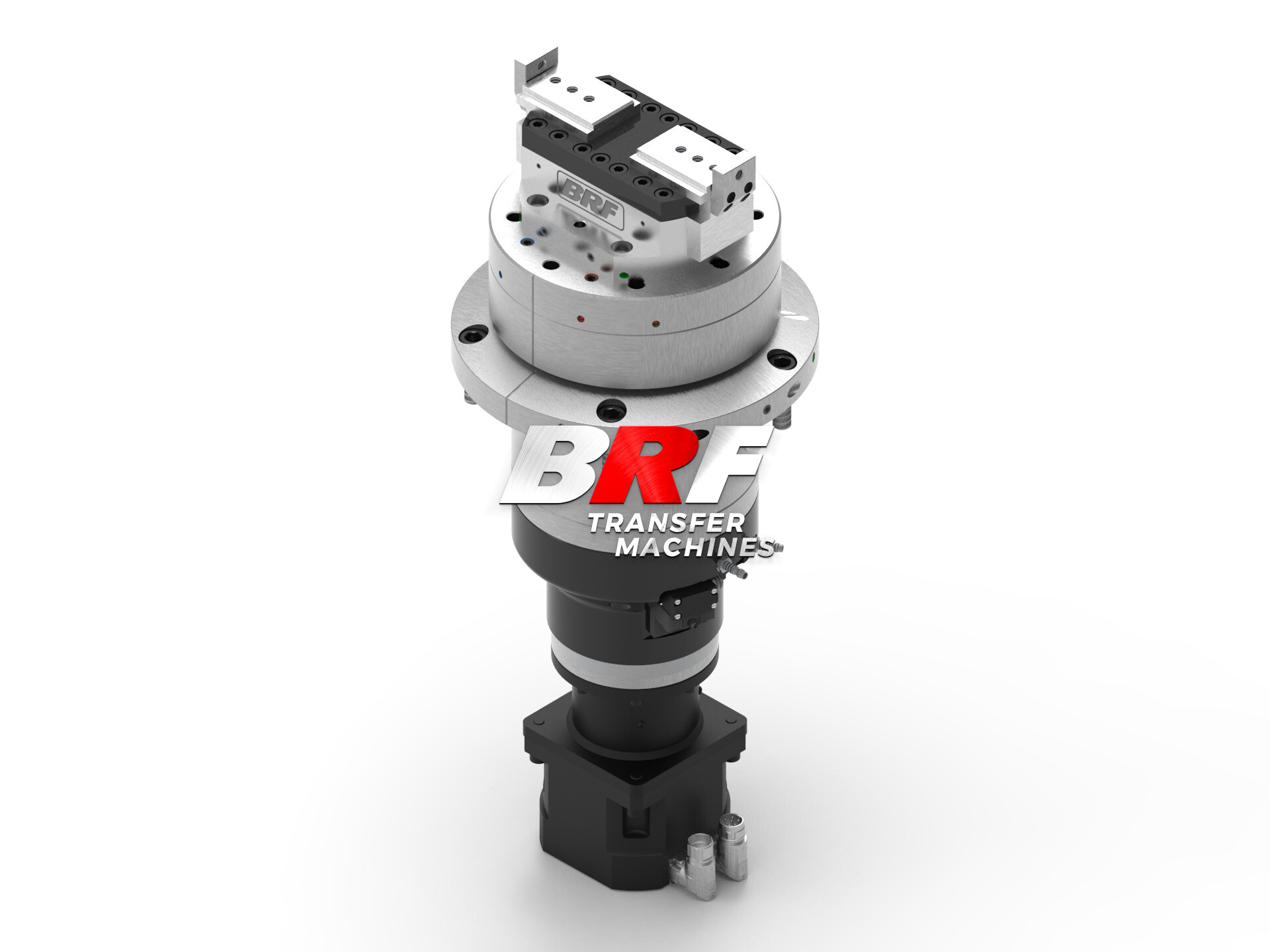

Stations with indexed tables (360 positions) arranged in 2 or 4 oil fuel drain lines and centralized automatic grease line.

-

3 horizontal XYZ modules with ISO40 or HSK63 tool holder.

-

Tool magazine with 20/100 places for each module, overall 60/300 tools.

-

ISO standard programming.

-

CNC Siemens or Fanuc or ESAutomotion

WHAT DISTINGUISHES 4 STATION SG FLEX FROM 3 MACHINING CENTERS?

| 4 STATION SG FLEX | 3 MACHINING CENTERS |

|---|---|

| 1 single machine capable of producing for 3. Less space used, high productivity | 3 machines, more space needed |

| 1 robot system or 1 operator | 3 robot systems or 3 operators for pieces loading/unloading |

| Complete machining of the piece: several simultaneous machining, less setup time | Secondary machining operation: after each machining the piece is loaded on the following machine, longer setup time |

Energy saving: :

|

Higher energy consumption:

|

| Tool magazine capacity: up to a maximum of 300 tools | Reduced tool magazine capacity |