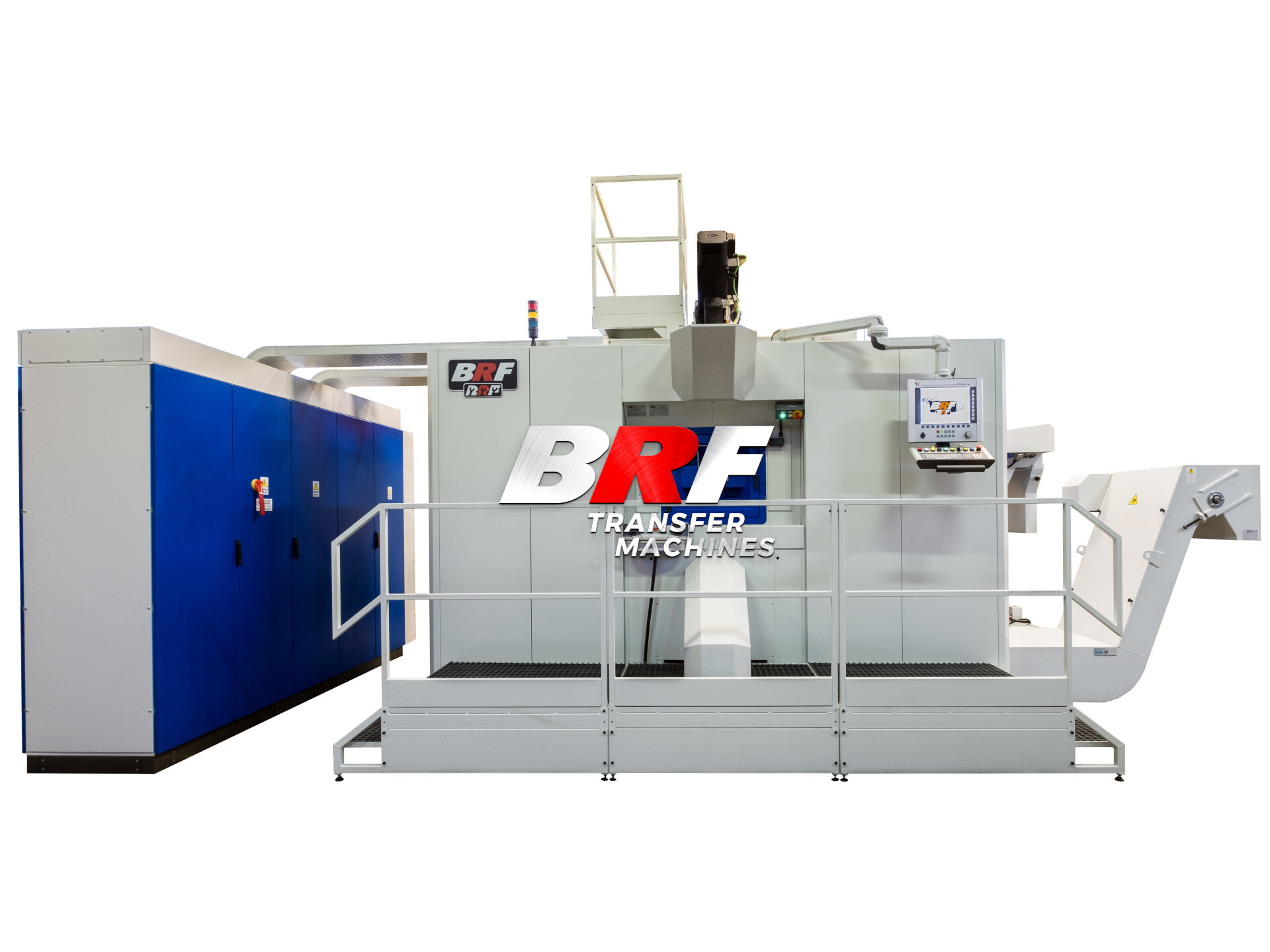

Traditional transfer machines are used for machining different kinds of pieces with high production volumes, reducing processing times.

Traditional transfer machines with HORIZONTAL AXIS distinguish themselves for the simplicity and the accessibility to tools. These machines, characterized by a rigid and compact construction, guarantee not only quality and precision in machining, but also offer flexibility, efficiency, productivity and autonomy in processing different materials such as steel, cast iron, aluminum and brass; thus satisfying the most varied processing requirements of the various sectors.